5G's Integral Role in Todays Industry (Industry 4.0): Revolutionizing Manufacturing with AI

The present Modern-Day Industry, often referred to as “Industry 4.0” or the Fourth Industrial Revolution, represents the use of advanced technologies to improve manufacturing processes and overall industrial efficiency. One of the key enablers of this revolution is the deployment of 5G technology, which brings unprecedented speed, low latency, and massive connectivity to the table. Coupled with Artificial Intelligence (AI), the potential of Industry 4.0 becomes limitless, empowering businesses to streamline operations, increase productivity, and create smart, autonomous systems.

In this article, we will explore the different Generations of Industry and its history in time, the crucial role of 5G within Industry 4.0, the impact of AI on various industries, and delve into a case study to exemplify this groundbreaking synergy.

Horizon’s 5G devices IR2005G and 25005G, along with other products, can play an integral role in today’s Industry 4.0 by revolutionizing manufacturing with AI. As part of the fifth-generation cellular network technology, these devices enable lightning-fast and reliable communication, paving the way for advanced automation and smart manufacturing processes

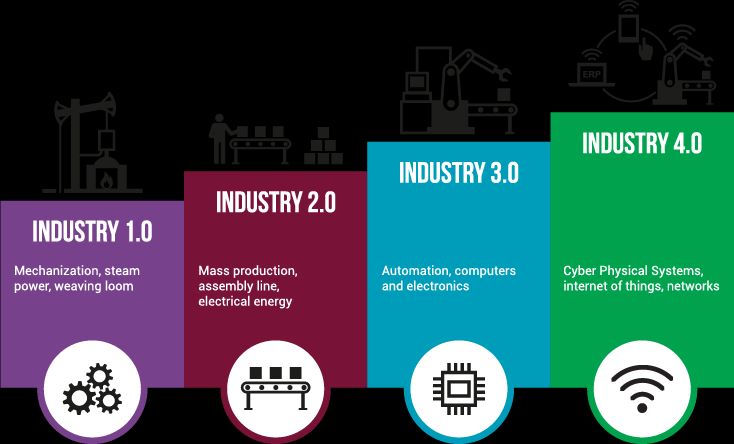

Industry 1.0: The First Industrial Revolution (Late 18th to early 19th century)

The first industrial revolution marked a significant shift from manual labor to mechanized production. It began with the invention of the steam engine and mechanized textile production. Factories emerged as a central hub for production, and the use of water and steam power transformed manufacturing processes.

Industry 3.0: The Third Industrial Revolution (Late 20th century)

The third industrial revolution was driven by the rise of computers, automation, and digital technologies. Electronics and information technology played a crucial role in transforming manufacturing processes. Programmable Logic Controllers (PLCs) and Computer Numerical Control (CNC) machines revolutionized production, enabling more precise and automated operations.

5G's Role within Industry 4.0

- Ultra-Fast Data Transfer: 5G’s remarkable data transfer speeds enable real-time communication between machines and devices, leading to swift decision-making and enhanced production processes. This ensures that data-heavy applications like AI-driven analytics can operate seamlessly, providing instant insights and enabling predictive maintenance.

- Low Latency: The low latency of 5G networks ensures near-instantaneous response times, which are critical for the precise and timely execution of commands in industrial automation systems. This feature allows manufacturers to deploy AI algorithms directly at the edge, reducing reliance on cloud-based solutions and minimizing downtime.

- Massive Connectivity: 5G’s ability to connect a vast number of devices simultaneously, known as Massive Machine-Type Communication (mMTC), allows industries to create extensive IoT networks. This connectivity revolutionizes supply chain management, logistics, and inventory control, resulting in optimized production cycles and reduced operational costs.

- Enhanced Flexibility and Mobility: The mobility offered by 5G enables the implementation of autonomous robots and vehicles in manufacturing processes. With AI-guided robots performing complex tasks, industries can achieve higher precision, safety, and efficiency.

Industry 2.0: The Second Industrial Revolution (Late 19th to early 20th century)

The second industrial revolution was characterized by the advent of electricity and mass production. The assembly line, pioneered by Henry Ford, enabled the efficient production of goods on a large scale. This period saw the rise of industries like steel, oil, and chemicals, which further fueled economic growth and urbanization.

Industry 4.0: The Fourth Industrial Revolution (Present)

Industry 4.0 represents the current era of manufacturing, characterized by the convergence of digital, physical, and biological technologies. It builds upon the foundation laid by Industry 3.0 and embraces concepts such as IoT, big data analytics, cloud computing, and artificial intelligence. The integration of these technologies allows for smart, interconnected systems that can optimize processes, improve decision-making, and enhance productivity.

AI's Impact on Industry 4.0

- Smart Manufacturing: AI plays a pivotal role in enabling smart manufacturing processes. It can analyze vast amounts of data from sensors and other connected devices to identify patterns, anomalies, and optimization opportunities. This leads to predictive maintenance, reducing downtime, and minimizing the risk of costly equipment failures.

- Quality Control and Defect Detection: AI-powered computer vision systems can inspect products for defects with unparalleled accuracy and speed. Manufacturers can maintain high-quality standards and reduce waste, ultimately boosting customer satisfaction.

- Supply Chain Optimization: AI-driven algorithms can optimize supply chain management by predicting demand fluctuations, identifying optimal transportation routes, and managing inventory levels efficiently. This leads to reduced lead times, minimized costs, and improved overall supply chain resilience.

- Human-Robot Collaboration: AI enables safe and productive human-robot collaboration in the workplace. Advanced AI algorithms ensure that robots can work alongside human employees, assisting in physically demanding or repetitive tasks, improving worker safety and productivity.

Case Study: Pioneering the Smart Factory with Industry 4.0 and AI

A global technology powerhouse, embarked on an ambitious journey to transform its manufacturing facilities into smart factories by leveraging the principles of Industry 4.0 and harnessing the power of Artificial Intelligence (AI). The company aimed to enhance efficiency, optimize production processes, and maintain a competitive edge in the rapidly evolving industrial landscape. This case study delves into This smart factory transformation, showcasing how they embraced cutting-edge technologies to achieve remarkable improvements in their manufacturing operations.